Cross Duct In-situ Measurement Technology

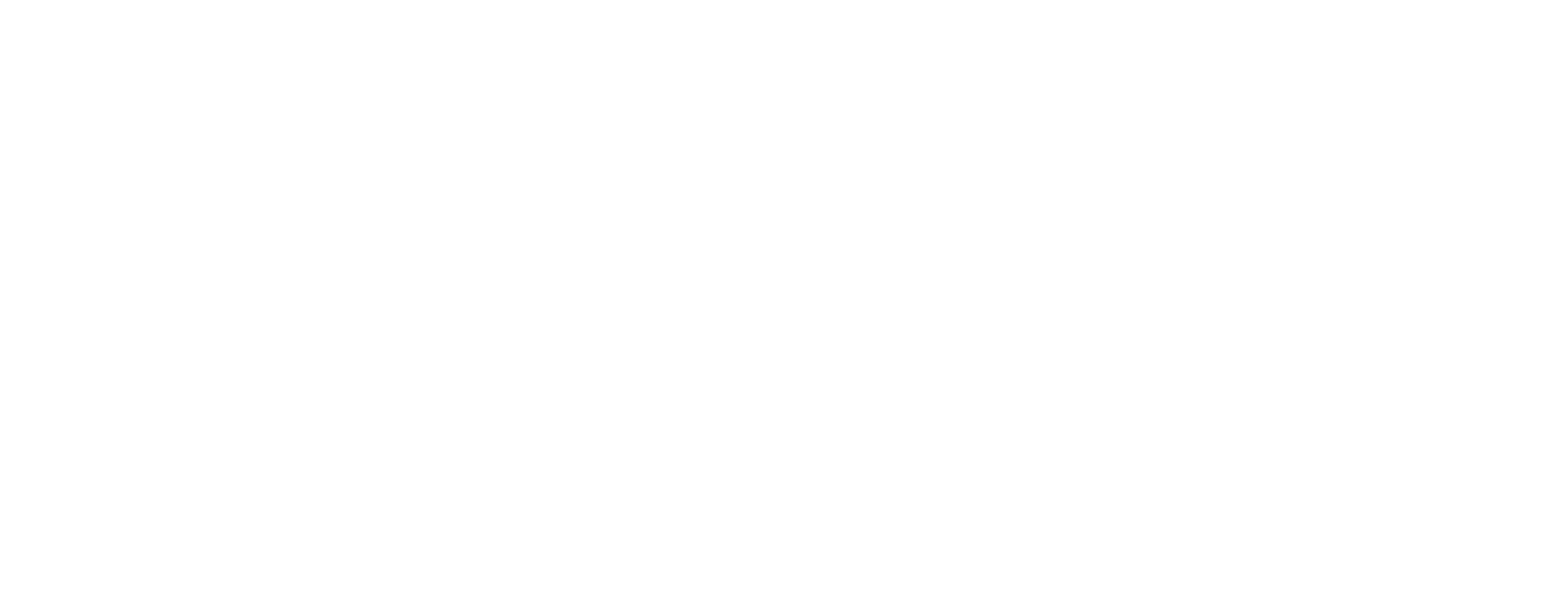

Cross Duct In-situ Measurement Technology brings simplicity to emissions monitoring by streamlining the process of measuring, recording, and providing a continuous gas measurement without having to extract gases from the process.

What is Cross Duct In-situ Measurement Technology?

Traditionally, Cross Duct In-situ Measurement Technology has been used for Process/ Operational purposes using products such as Tunable Diode Lasers (TDL) or Differential Optical Absorption Spectroscopy (DOAS).

- IPCEMS is taking these products and using them for compliance. Under the regulations set forth by the Environmental Protection Agency (EPA) in 40 CFR Part 60 and 40 CFR Part 75, an IPCEMS (Integrated Path Continuous Emission Monitoring System) refers to a system that measures gas emissions directly within the process, rather than in the flue gas after combustion.

- These systems provide data for regulatory compliance and operational purposes.

- IPCEMS bring simplicity, increased accuracy, and operational cost savings to emissions monitoring.

Cross Duct In-situ Measurements

As opposed to extractive process CEMS, the Cross Duct In-situ Measurement Technology measures the gas concentrations in-situ. The benefits are multiple:

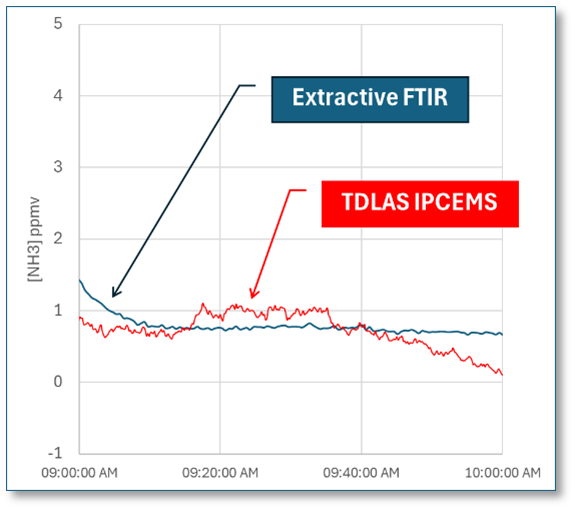

- Improved accuracy: by sampling the gas through the entire diameter of the stack, inaccuracies typically associated with extractive methods (stack stratification, sample conditioning and transport errors) are mitigated.

- Greater Cost-Effectiveness: Cross Duct In-situ Measurement Technology can be more cost-effective compared to direct extractive process systems, especially for facilities in which installation and maintenance of direct monitoring equipment is impractical or excessively expensive.

- Greater Flexibility: These systems offer flexibility in monitoring multiple pollutants through a single framework, reducing the need for multiple direct measurement devices.

Cross Duct In-situ Measurement Technology for US EPA 40CFR Part 60

Performance Specification 2 (PS-2) under 40 CFR Part 60 Appendix B outlines requirements for optical path calibration for Continuous Emission Monitoring Systems (CEMS). IPCEMS specifications may fall under these guidelines, requiring calibration checks to ensure accuracy over the full length of the optical path in the duct or stack.

40 CFR Part 60 Performance Specification 18 (PS-18) specifically addresses the calibration of optical paths in IPCEMS. This includes ensuring that the calibration cell or gas interface passes along the entire path length used for emissions measurements to account for any potential interference or drift in measurement results. Daily calibration requirements generally specify that the entire sampling system, including the optical path, must be validated to ensure that measurements are accurate across the full span of the IPCEMS path.

Cross Duct In-situ Measurement Technology for US EPA 40CFR Part 75

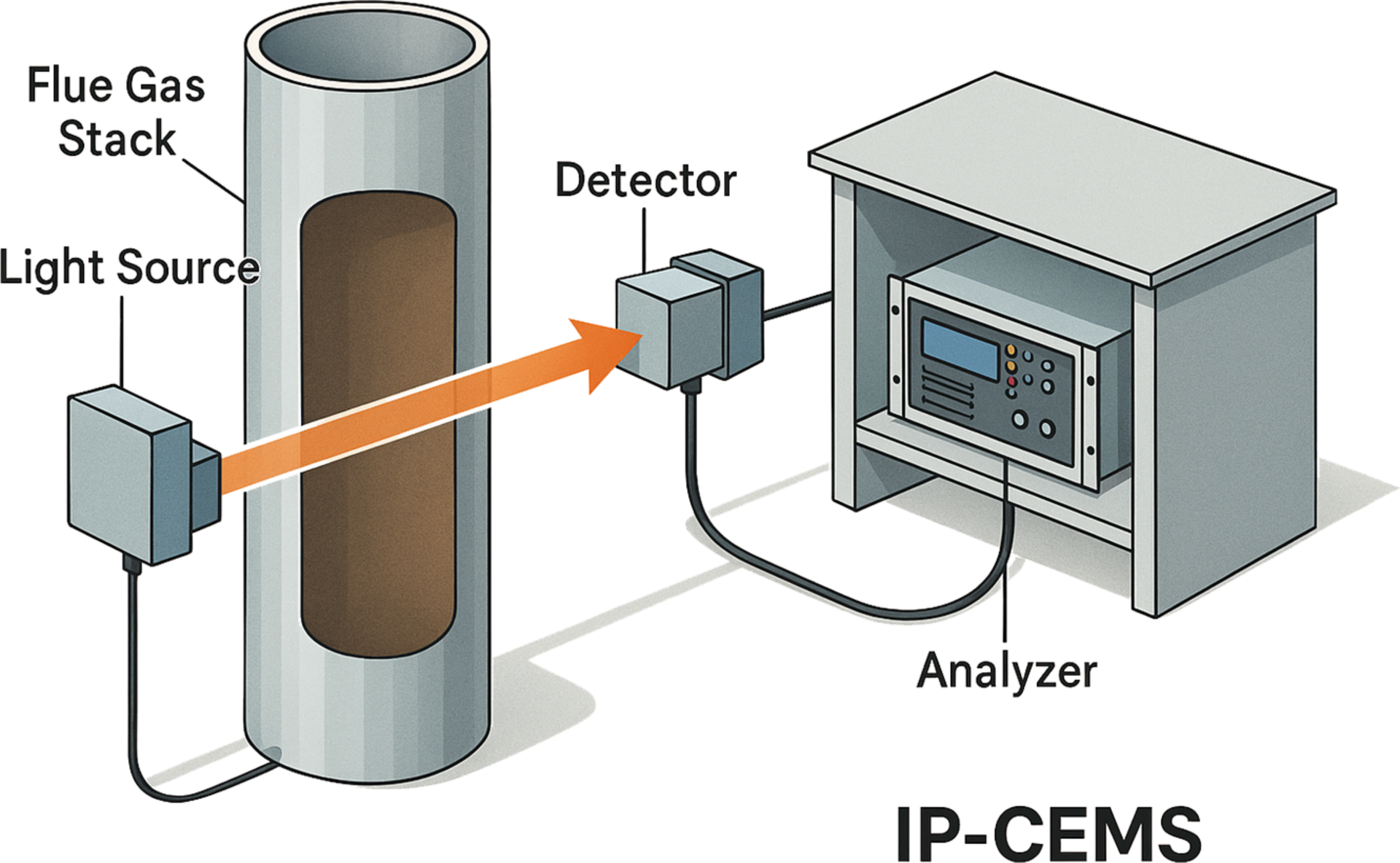

Until now, Cross Duct In-situ Measurement Technology had not been used for EPA 40CFR part 75 applications because, as the difference of Part 60 (PS18 (Title 40 Chapter I Subchapter C Part 60 Appendix B to Part 60), Part 75:

- Part 75 Appendix A, Section 6.3.1- Discussing calibration requirements states that “For in-situ type monitors, […] Equation A-5 of this appendix [is used to] determine the calibration error at each concentration once each day.”

- Equation A-5 does not provide pathlength differential compensation provision (as is proposed in Part 60 PS18 Eq. 4)

- Additionally, when the Electronic Data Report (EDR) is evaluated in the Emissions Collection and Monitoring Plan System (ECMPS), daily calibration results will yield a Critical Error if "gas cylinders [contain] concentrations outside [of] the required percentage of the Monitoring Span Value.

Cross Duct In-situ Measurement Technology for Process Applications

The benefits of in situ measurement over extractive sampling measurement are:

- Improved accuracy: by sampling the gas through the entire diameter of the stack, inaccuracies typically associated with extractive methods (stack stratification, sample conditioning and transport errors) are mitigated.

- Improved Temporal Resolution: IP-CEMS provide updated real-time response data every 10 seconds with no added sampling transport time, pollutants loss caused by sample conditioning, or incorrect readings smoothed out by gases adsorption / desorption in the sampling line.

Our Cross Duct In-situ Measurement Products

Interested in our services? We’re here to help!

We want to know your needs exactly so that we can provide the perfect solution. Let us know what you want and we’ll do our best to help.