The CEMTEK Difference for

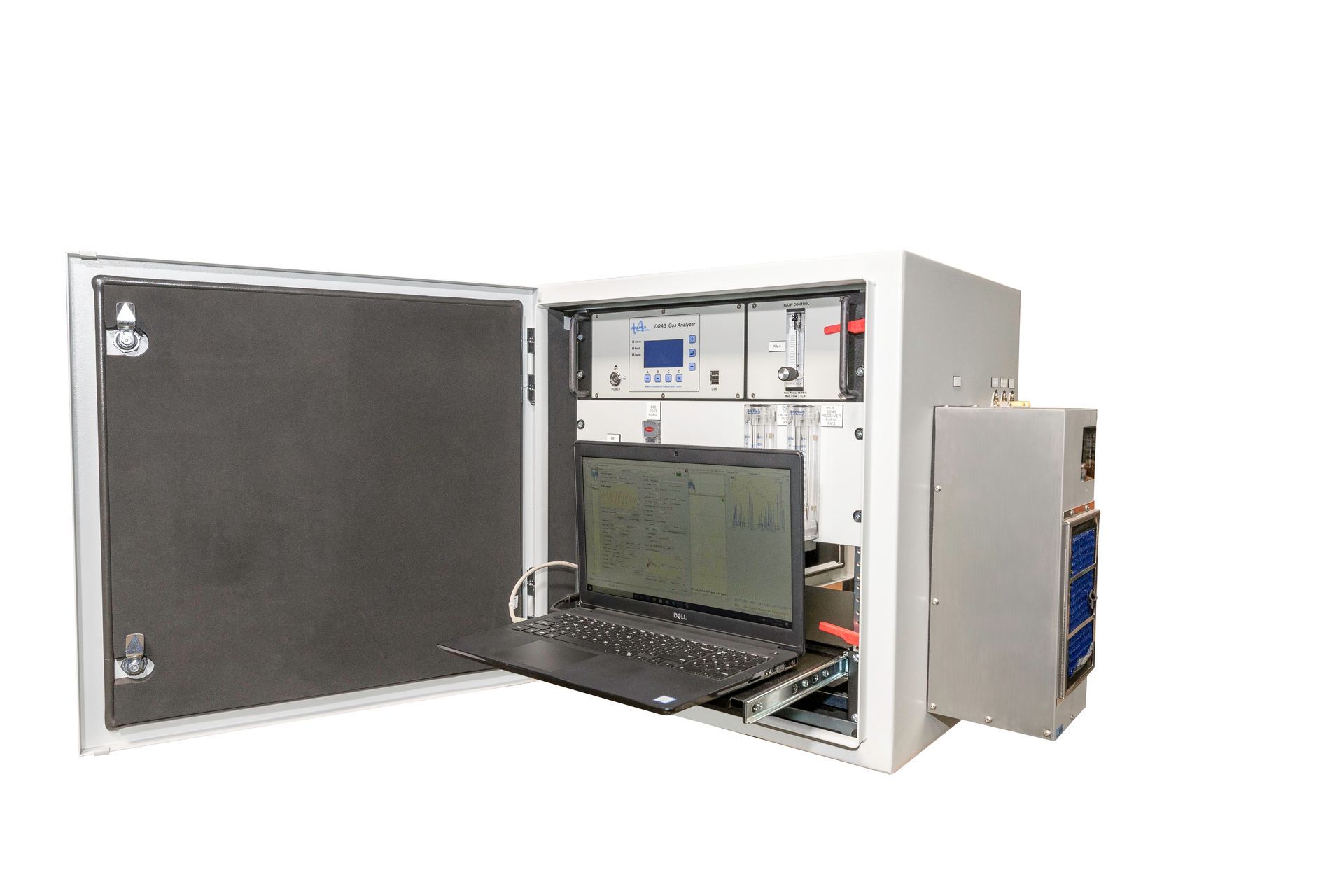

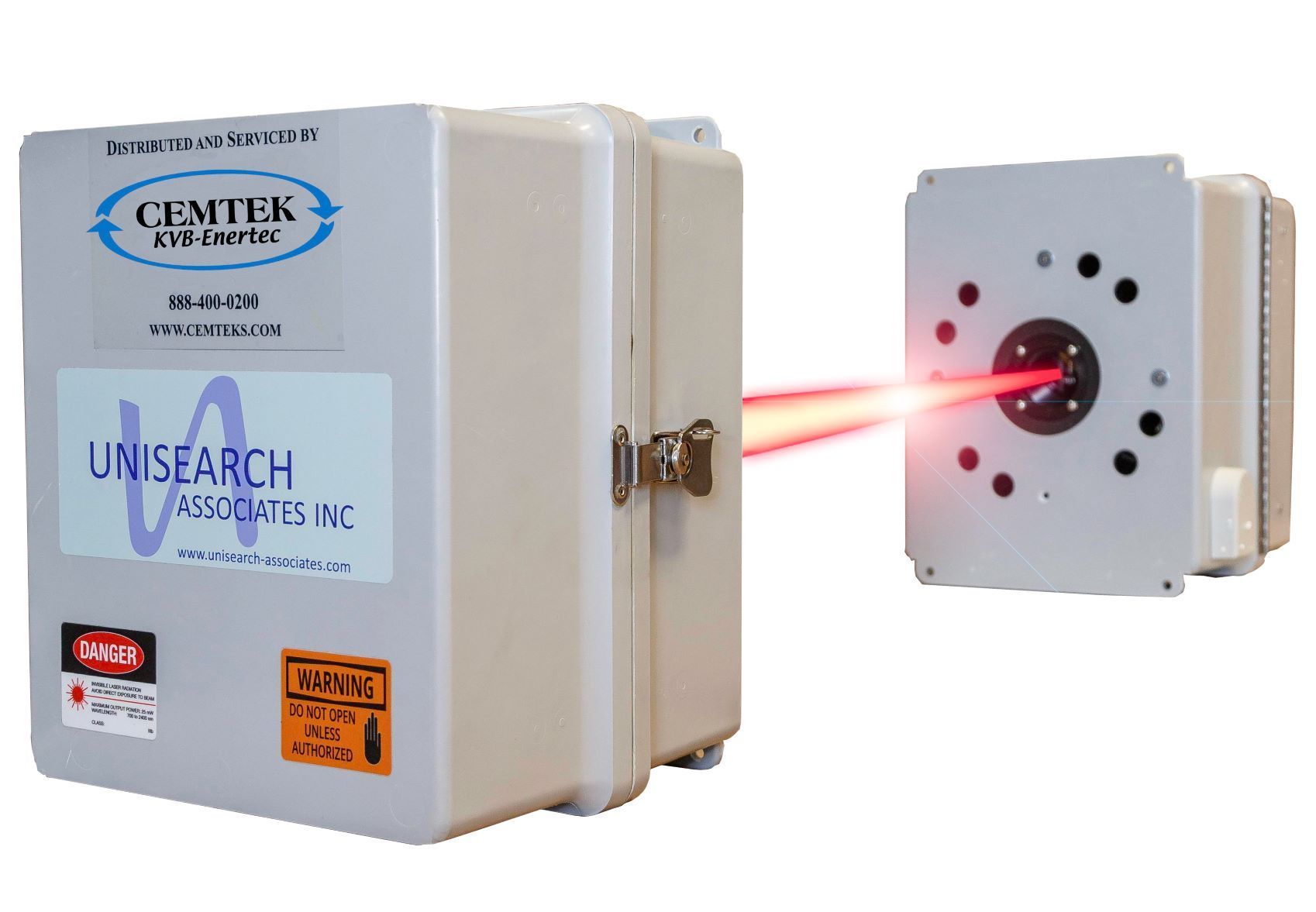

Cross Duct In-situ Measurement Technology

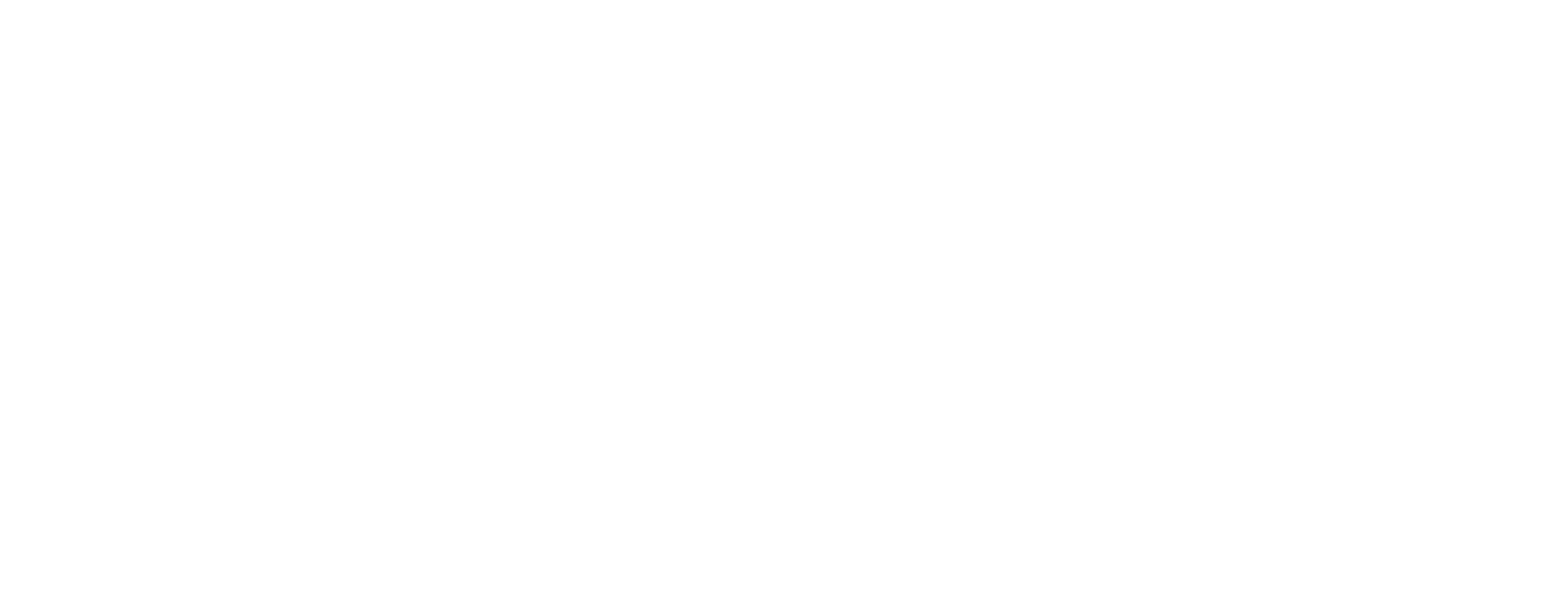

The CEMTEK Difference

- 20+ Years of Experience. Cemtek certified its first IPCEMS (an NH3 TDL) application in 2005, SCAQMD. We now have over twenty years of field experience integrating, commissioning and supporting Cross Duct In-situ Measurement Technology including IPCEMS for 40CFR Part 60 applications.

- Our IPCEMS Measure:

NO, NO2 (NOx) & SO2

CO, CO2, O2

NH3

HCl, HCN

- Proven and Accurate Results

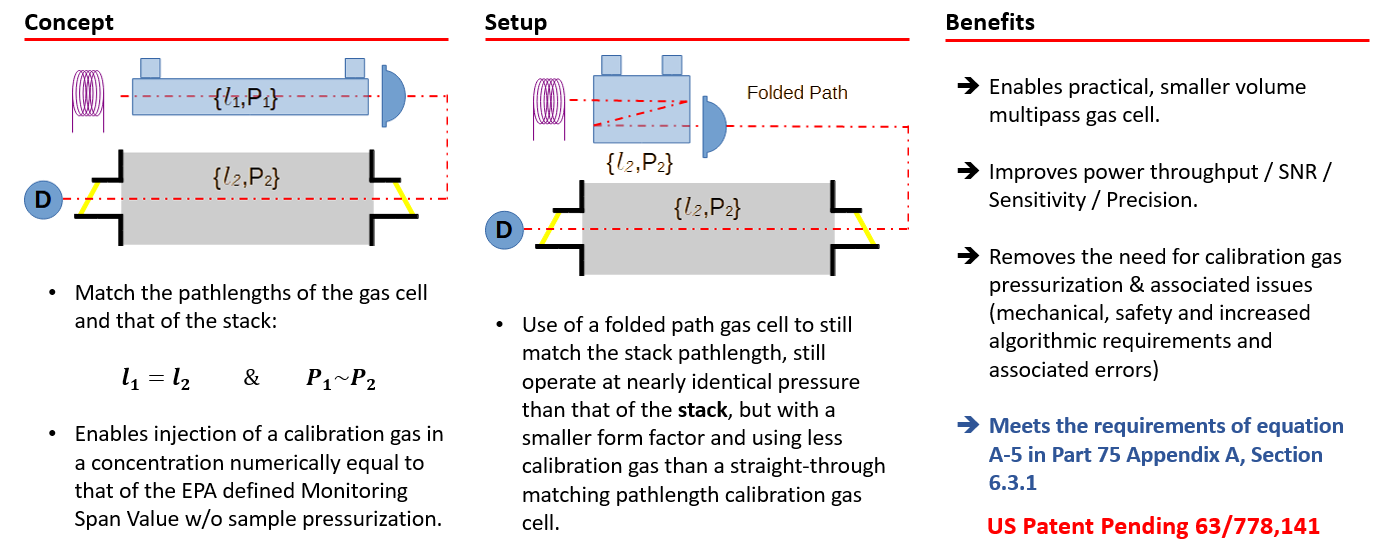

- US Patent Pending 63/778,141

CEMTEK KVB-Enertec uses a solution based on the Beer Lambert's Law. This solution is proven to work and is compliant with Part 75 language to the letter.

There are no interpretations or stretching of the limits of the Part 75 definitions.

In order to use an IPCEMS for a Part 75 application, one must use a calibration gas cylinder containing a gas concentration numerically equal to the Monitoring Span Value as defined in Section 5.2 of Appendix A to Part 75, Title 40.

SOLUTION BASED

Benefits of Beer Lambert's Law

Other Cross Duct In-situ Measurement

Technology Integrators

Other Cross Duct In-situ Measurement Technology Integrators use a solution based on the Ideal Gas Law, which requires the pressurization of gas and more complex algorithms. This approach may appear to work but it is fraught with complex errors.

More importantly, it is not in compliance with the actual language of Part 75.

Additionally, when the Electronic Data Report (EDR) is evaluated in the Emissions Collection and Monitoring Plan System (ECMPS), daily calibration results will yield a Critical Error if "gas cylinders [contain] concentrations outside [of] the required percentage of the Monitoring Span Value"*

Section 5.2 of Appendix A to Part 75, Title 40 specifically defines the Monitoring Span Value as a percentage of the span of the analyzer.

As a result, this intrinsically increases the uncertainty of the measurement.