Integrated Path CEMS

For Parts 60 & 75

The CEMTEK Difference:

- 20+ Years of Experience. Cemtek certified its first IPCEMS (an NH3 TDL) application in 2005, SCAQMD. We now have over twenty years of field experience integrating, commissioning and supporting IPCEMS for 40CFR Part 60 applications.

- NO, NO2 (NOx) & SO2

- CO, CO2, O2

- NH3

- HCl, HCN

- Proven and Accurate Results

- US Patent Pending 63/778,141

Not All IPCEMS Are

Created Equal

Other IPCEMS Integrators

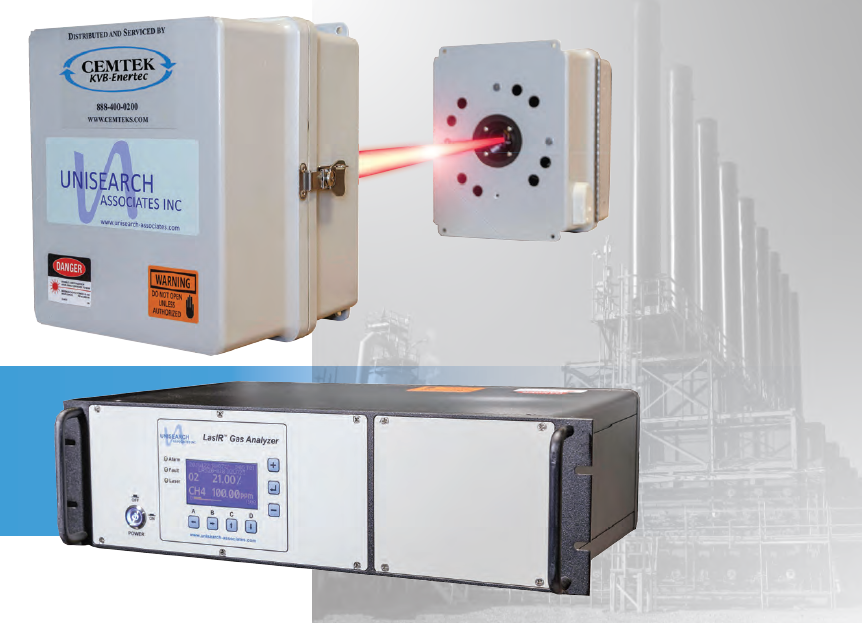

Other IPCEMS Integrators use a solution based on the Ideal Gas Law, which requires the pressurization of gas and more complex algorithms. This approach may appear to work but it is fraught with complex errors. More importantly, it is not in compliance with the actual language of Part 75. Additionally, when the Electronic Data Report (EDR) is evaluated in the Emissions Collection and Monitoring Plan System (ECMPS), daily calibration results will yield a Critical Error if "gas cylinders [contain] concentrations outside [of] the required percentage of the Monitoring Span Value"*

Section 5.2 of Appendix A to Part 75, Title 40 specifically defines the Monitoring Span Value as a percentage of the span of the analyzer.

As a result, this intrinsically increases the uncertainty of the result.

The CEMTEK Difference

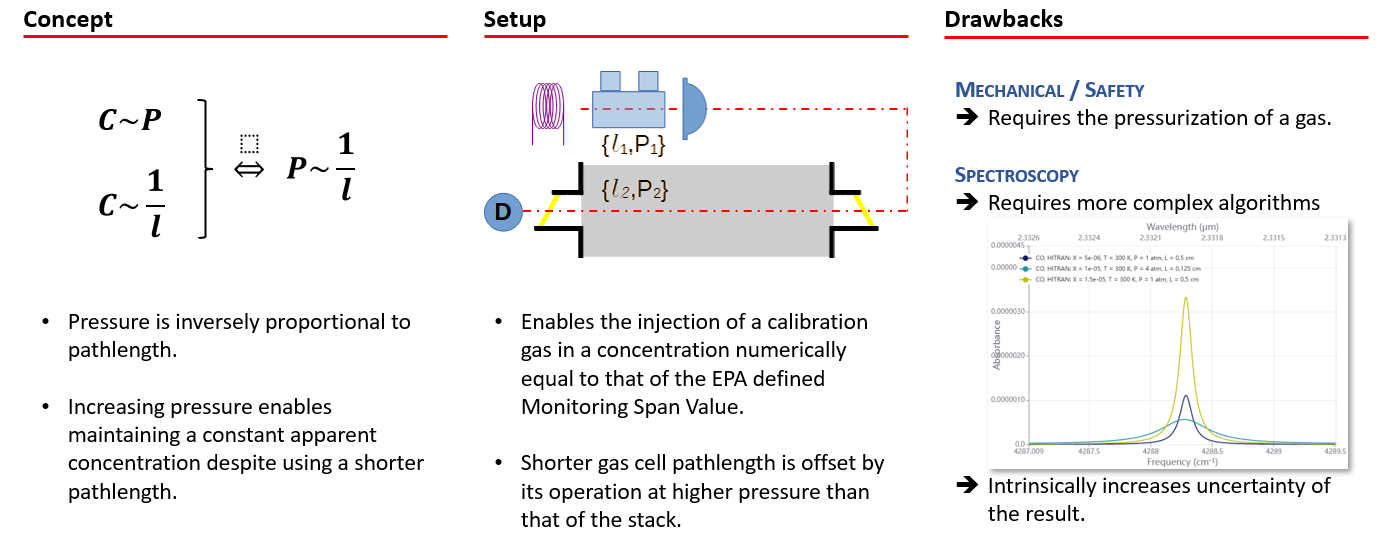

CEMTEK KVB-Enertec has over twenty years of experience integrating custom IPCEMS and uses a solution based on the Beer Lambert's Law. This solution is proven to work and is compliant with Part 75 language to the letter. There are no interpretations or stretching of the limits of the Part 75 definitions. In order to use an IPCEMS for a Part 75 application, one must use a calibration gas cylinder containing a gas concentration numerically equal to the Monitoring Span Value as defined in Section 5.2 of Appendix A to Part 75, Title 40.

Being a CEMS Integrator allows us to service your needs by customizing a CEMS system that is of the most benefit to your application. With over fifty years of CEMS experience, we understand that IPCEMS do not work for all applications.

Therefore, CEMTEK has a Plan B with the same operational cost benefits than an IPCEMS that does meet Part 75 requirements to the letter.

CEMTEK has proudly partnered with Durag LaserCEM(R). Please below to learn more.

Benefits of Beer Lambert's Law

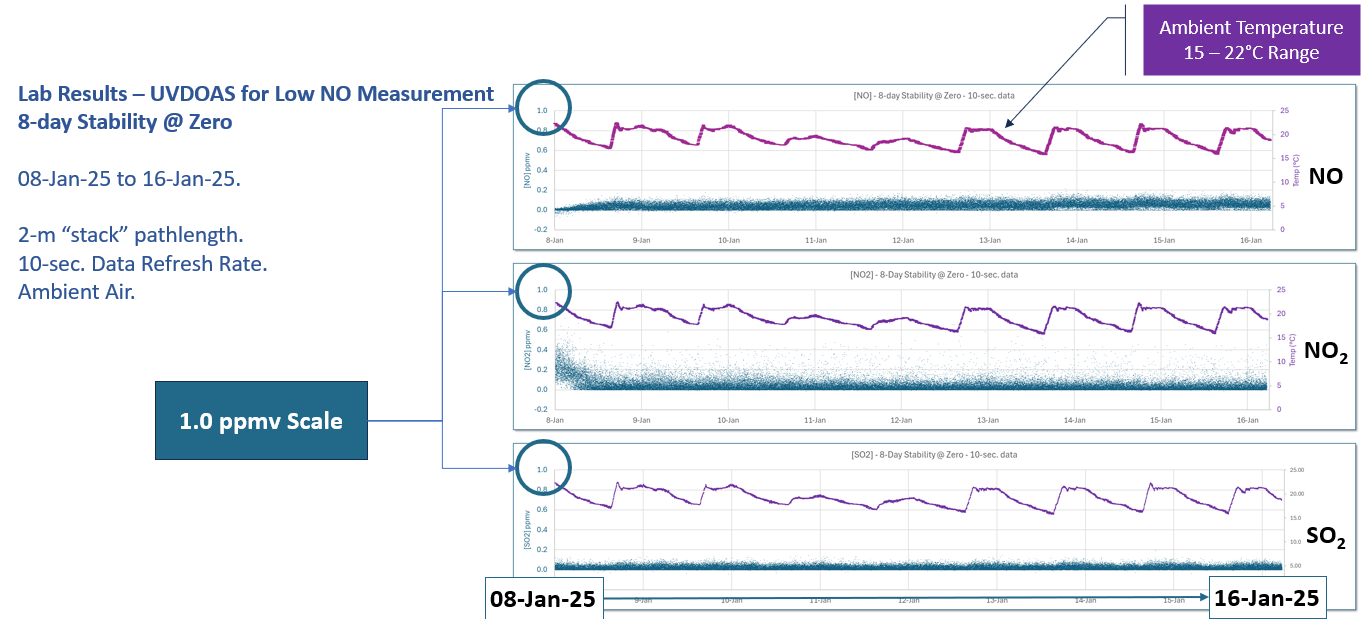

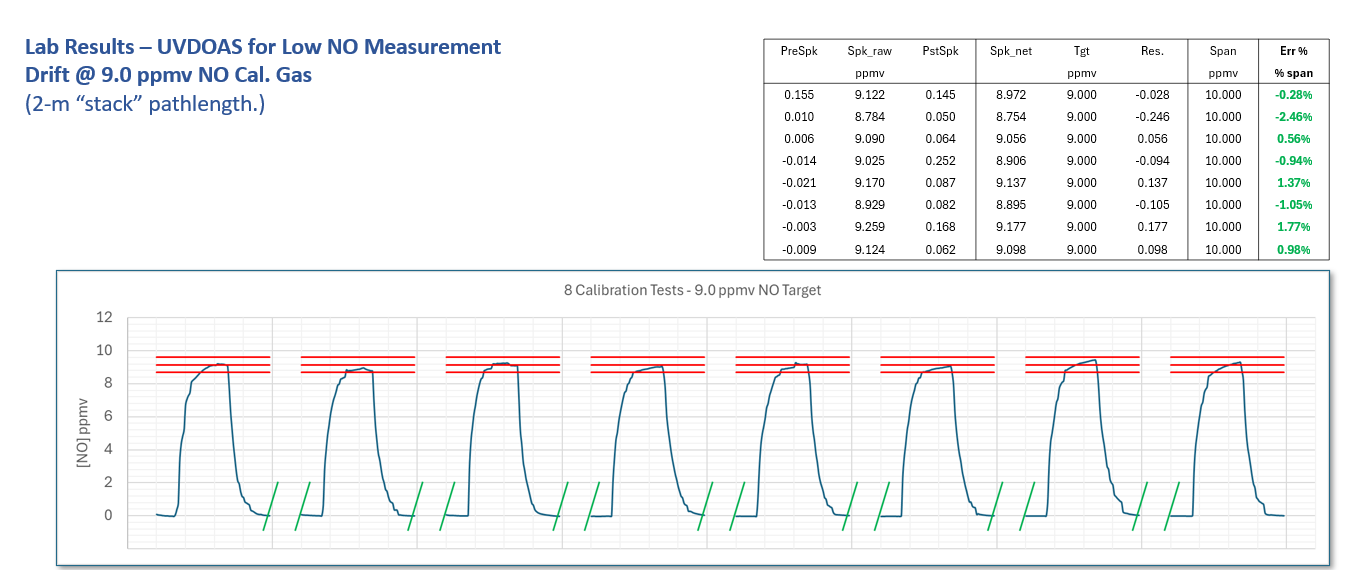

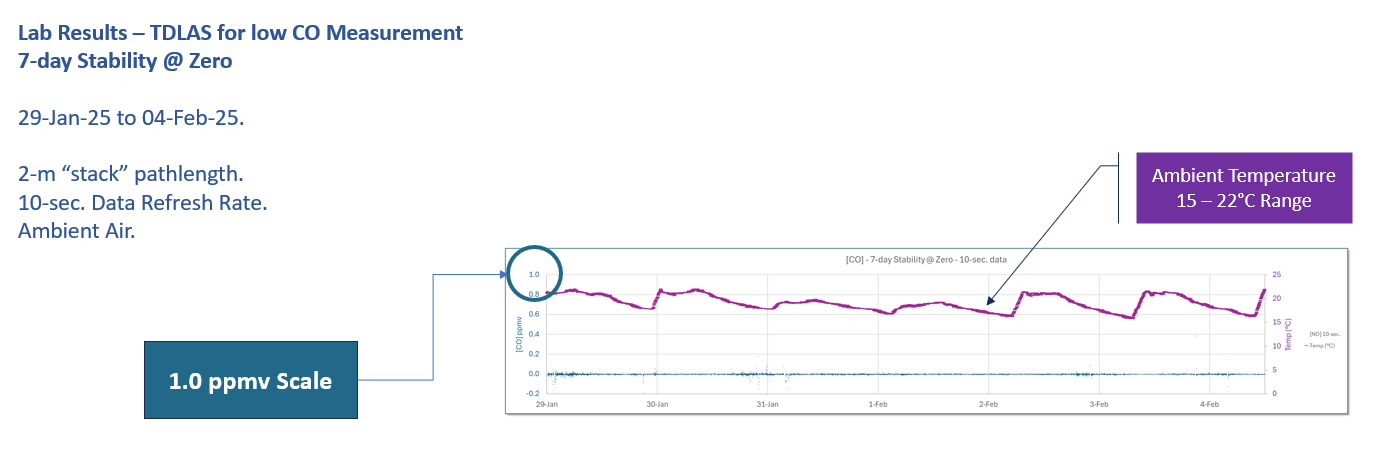

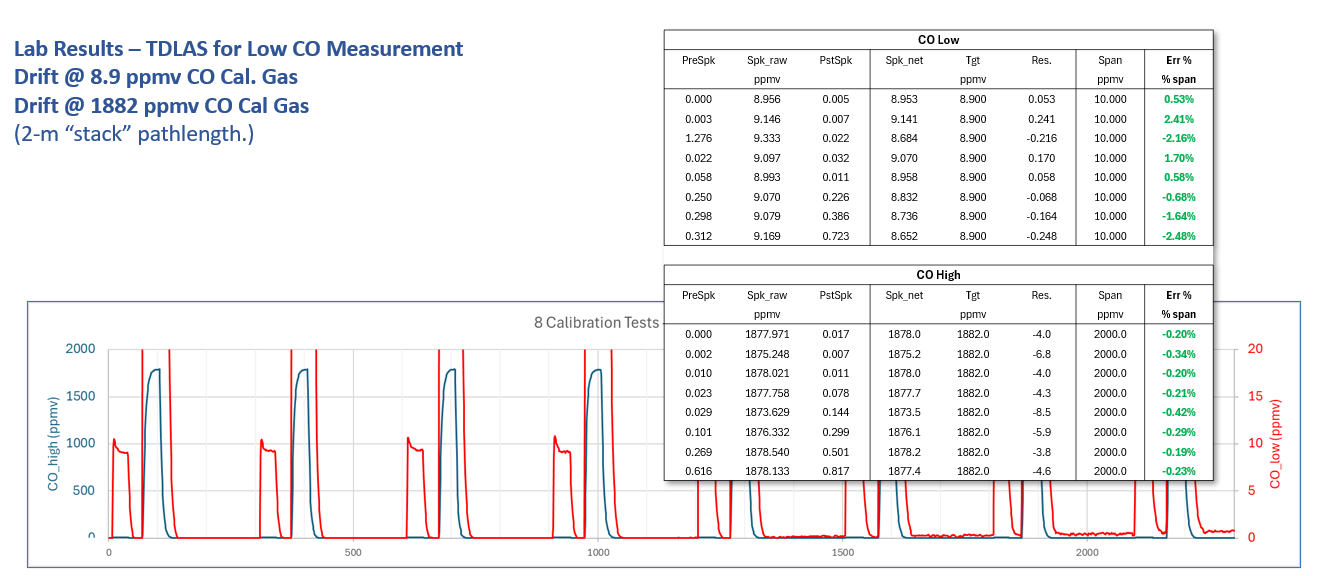

Successful Lab Results

CEMTEK and the Durag Group's LaserCEM®

Cemtek has proudly partnered with the Durag Group's LaserCEM® to bring you a simpler and accurate CEMS solution for Part 75 and Part 60!

The Durag Group's LaserCEM® to bring you a simpler and accurate CEMS solution for Part 75 and Part 60!

The LaserCEM® is a turnkey, pre-calibrated multi-gas CEMS solution for regulatory compliance of industrial emissions.

The LaserCEM® combines two patented technologies: Optical Feedback Cavity Enhanced Absorption Spectroscopy (OFCEAS®) and Low-Pressure Sampling (LPS®), enabling high resolution, interference-free, fast, and highly sensitive spectral analysis.

For more details, please refer to the LaserCEM® Page in the Products category of our website.

Description of IPCEMS

IPCEMS

IPCEMS refer to systems that measures gas emissions directly within the process, rather than in the flue gas after combustion.

IPCEMS measure the gas concentrations in-situ.

- Improved accuracy:

- Samples the entire width of the stack (averaging out stratification)

- Removes sample conditioning and transport errors.

- Greater Cost-Effectiveness:

- IPCEMS can be more cost-effective compared to direct CEMS, especially for facilities in which installation and maintenance of direct monitoring equipment is impractical or excessively expensive.

- Greater Flexibility:

- Monitors multiple pollutants through a single framework, reducing the need for multiple direct measurement devices.

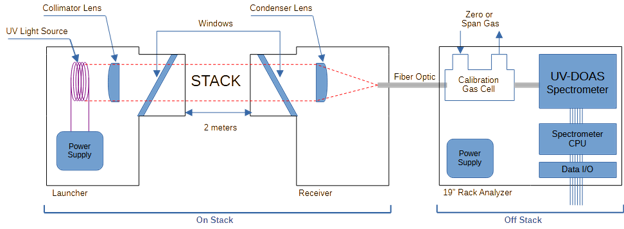

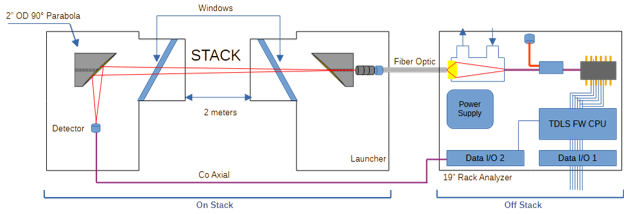

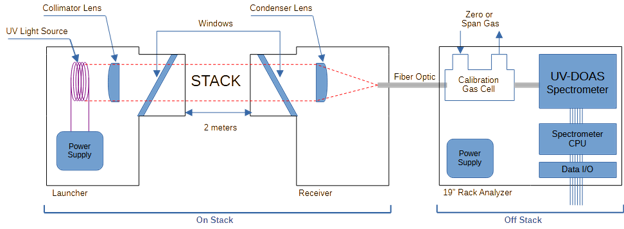

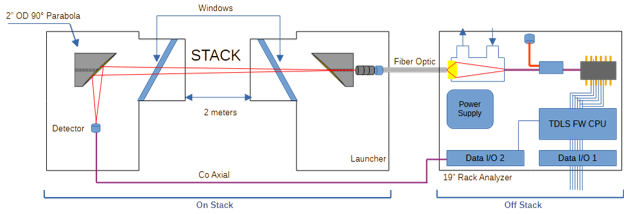

All IP-CEMS include:

- A light source.

- A means to inject the light emitted by the source into and across the stack.

- A means of collecting the light radiations modified by the presence of gas molecules in the stack.

- A means to process this information into chemical measurements.

- A calibration gas cell located in line with the light path from source to detector, including the light path through the stack.

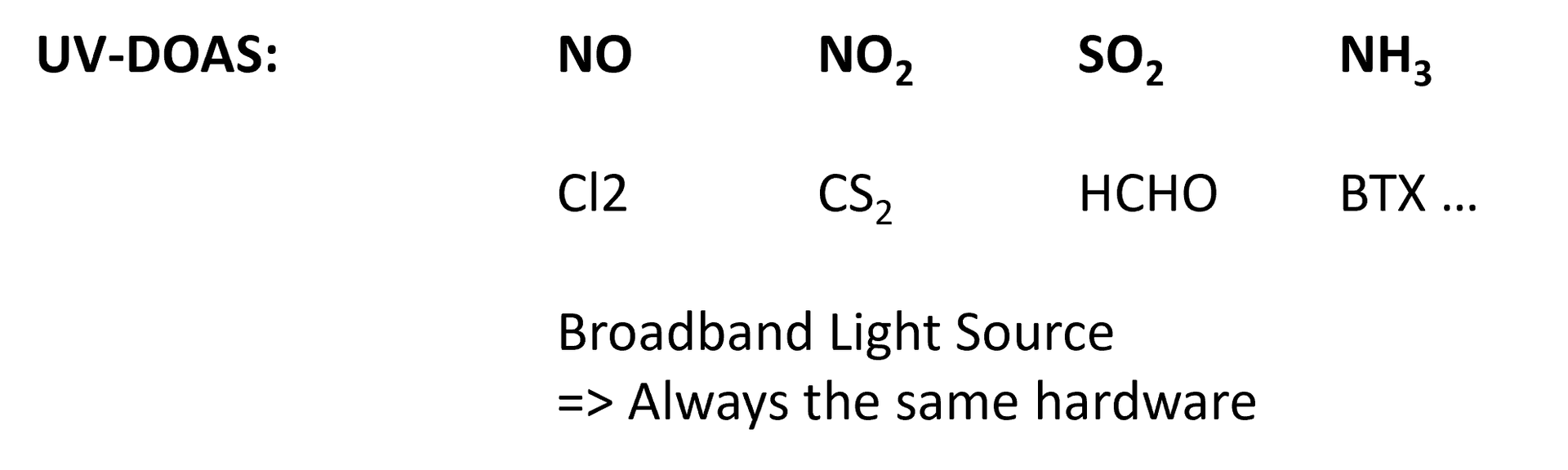

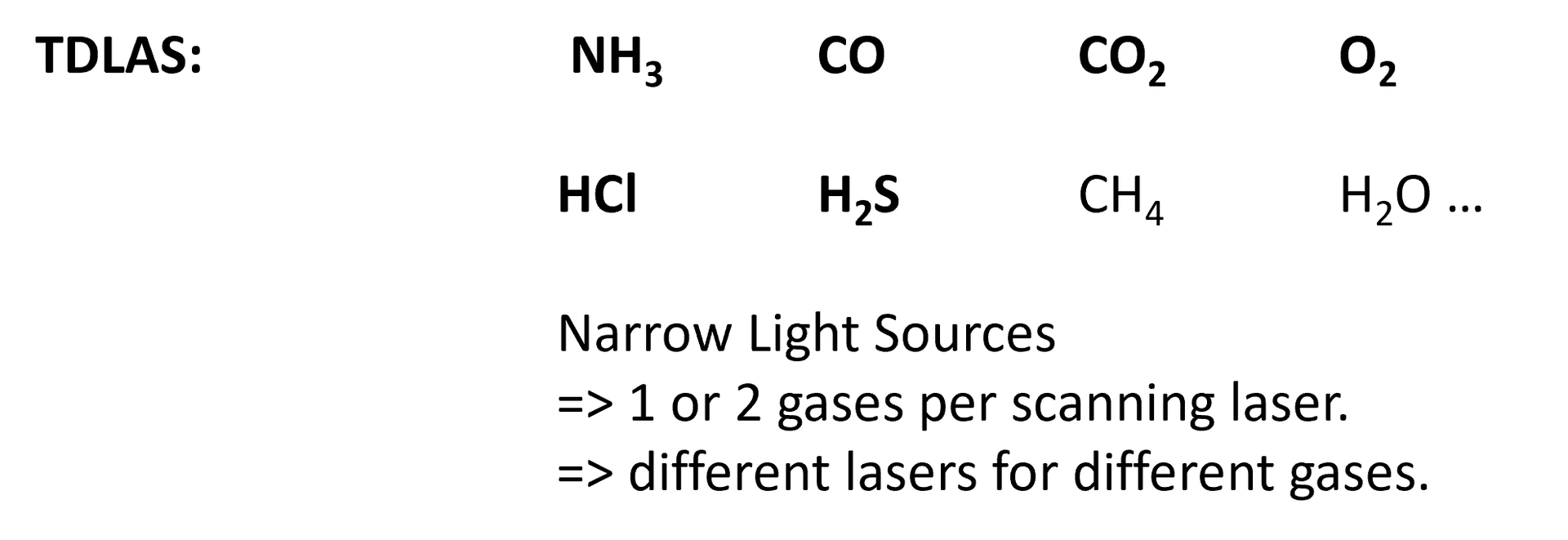

Gases Measured

Economic Benefits

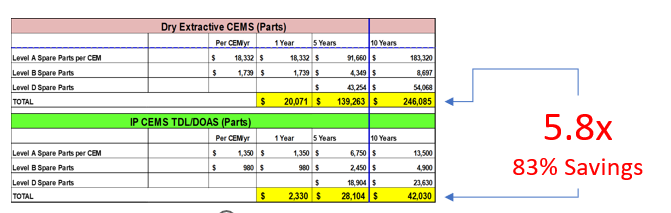

Consumable Spare Parts (level A)

Lower High Failure Probability Parts (level B)

All Parts (level D)

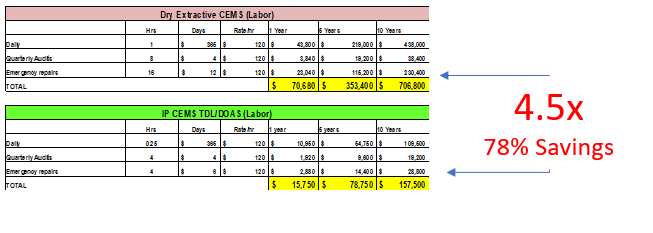

Service & Maintenance Labor Costs

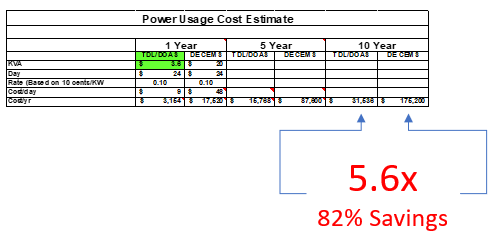

Power Usage

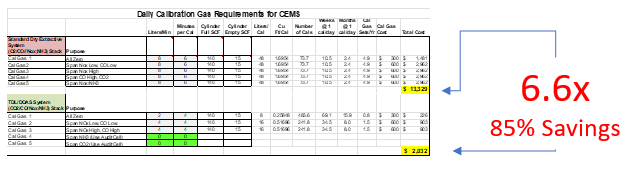

Calibration Gases

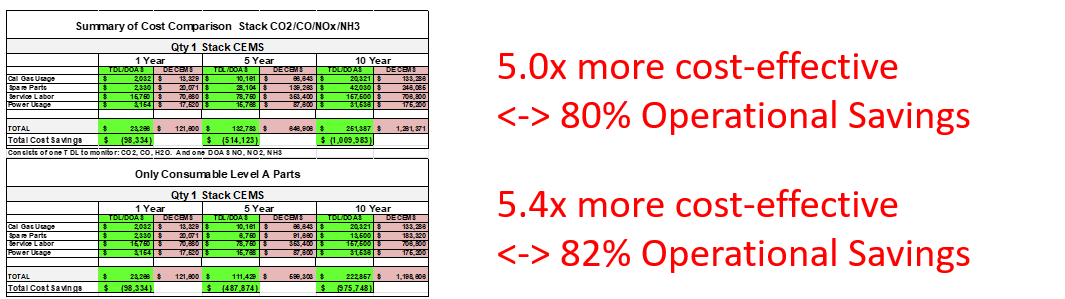

Summary Of Cost Comparison

Interested in an IPCEMS? We’re here to help!

We want to know your needs exactly so that we can provide the perfect solution. Fill out our Application Data Sheet and we will start the process right away.